You have reached the maximum number of views available on this site without registering.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

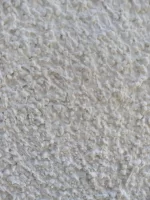

1.5mm silicone render, cracking all over

- Thread starter rb7

- Start date

Olican

Private Member

You have reached the maximum number of views available on this site without registering.

Mr White

Active Member

You have reached the maximum number of views available on this site without registering.

Mr White

Active Member

You have reached the maximum number of views available on this site without registering.

You have reached the maximum number of views available on this site without registering.

You have reached the maximum number of views available on this site without registering.

You have reached the maximum number of views available on this site without registering.

You have reached the maximum number of views available on this site without registering.

Mr White

Active Member

You have reached the maximum number of views available on this site without registering.

vfr12

MOTORC*NT

You have reached the maximum number of views available on this site without registering.

Mr White

Active Member

You have reached the maximum number of views available on this site without registering.

tapit

Well-Known Member

You have reached the maximum number of views available on this site without registering.

You have reached the maximum number of views available on this site without registering.

vfr12

MOTORC*NT

You have reached the maximum number of views available on this site without registering.

Mr White

Active Member

You have reached the maximum number of views available on this site without registering.

vfr12

MOTORC*NT

You have reached the maximum number of views available on this site without registering.

Mr White

Active Member

You have reached the maximum number of views available on this site without registering.

Arti

Well-Known Member

You have reached the maximum number of views available on this site without registering.

vfr12

MOTORC*NT

You have reached the maximum number of views available on this site without registering.

Plasterers1StopShop

Well-Known Member

You have reached the maximum number of views available on this site without registering.

You have reached the maximum number of views available on this site without registering.

Mr White

Active Member

You have reached the maximum number of views available on this site without registering.

Rigsby

TPF Special Forces

You have reached the maximum number of views available on this site without registering.

You have reached the maximum number of views available on this site without registering.

You have reached the maximum number of views available on this site without registering.

You have reached the maximum number of views available on this site without registering.

Rigsby

TPF Special Forces

You have reached the maximum number of views available on this site without registering.

You have reached the maximum number of views available on this site without registering.

vfr12

MOTORC*NT

You have reached the maximum number of views available on this site without registering.

vfr12

MOTORC*NT

You have reached the maximum number of views available on this site without registering.

You have reached the maximum number of views available on this site without registering.

Mr White

Active Member

You have reached the maximum number of views available on this site without registering.

vfr12

MOTORC*NT

You have reached the maximum number of views available on this site without registering.

Mr White

Active Member

You have reached the maximum number of views available on this site without registering.

You have reached the maximum number of views available on this site without registering.