Hello Flynnyman

Sure, that's one of the main application area for Bauwer.

A key characteristic of older buildings is the widespread use of 'breathable' (or 'permeable') materials, which are able to absorb moisture and release it again without damaging the building (solid stone and solid bricks walls, no cavity). By contrast, most modern buildings (with a cavity) rely on materials that keep moisture out.

Maintaining the building's ability to control moisture levels in this way is fundamental to its effective thermal performance. When looking after or making changes to the older home it is critical to use materials that are well compatible with it eg breathable.

Bauwer is a highly breathable martial with vapour permeability coefficient of 4. Also Bauwer is much lighter vs Lime, delivering a considerable thermal performance and application efficiency. Lime is also one of the key components of Bauwer as well as expanded Perlite which delivers thermal performance.

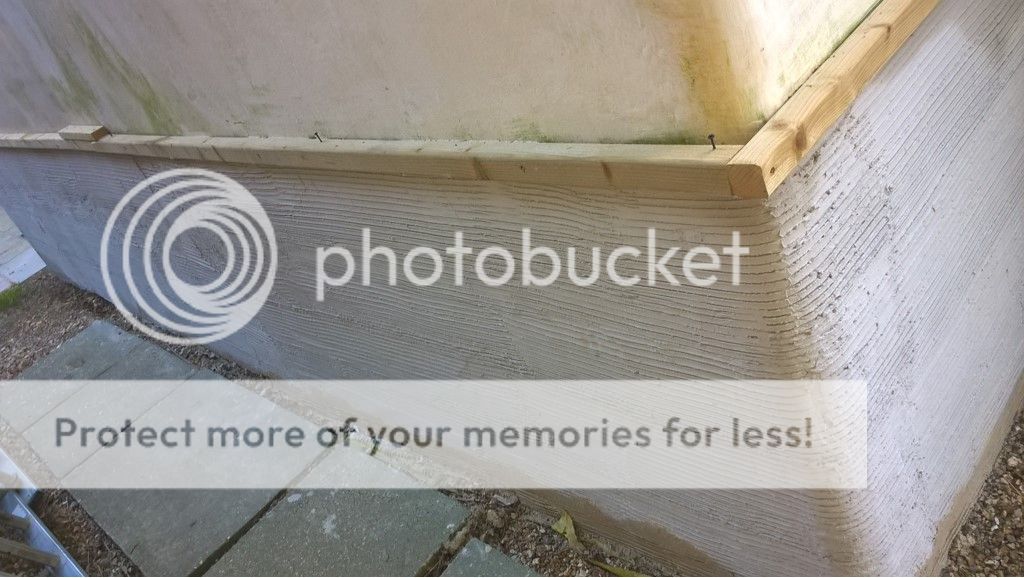

There are number of customer reviews, who applied Bauwer in older buildings:

https://bauwer.co.uk/Reviews.html

Also Bauwer material is now available from our official distributor

@Plasterers1StopShop

Best regards,

Alexander